Sustainable Cap Mould Innovation by Qhpreformmould for Global Industries

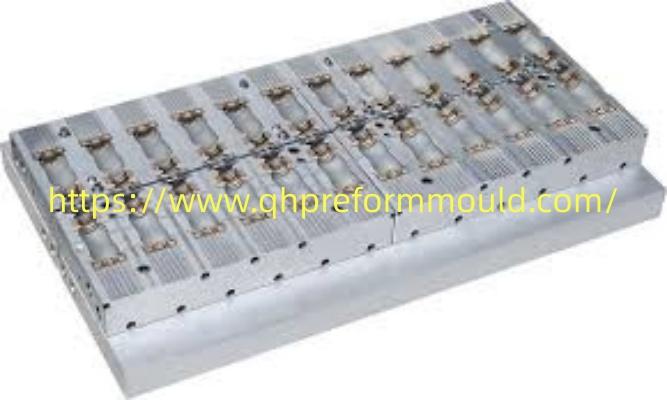

In modern packaging manufacturing, the Cap Mould plays an essential role in ensuring precision and consistency during the production of closures used across industries. A reliable mould determines the accuracy of each component, influencing the overall appearance, sealing performance, and durability of the finished packaging. As the global market continues to emphasize both functionality and sustainability, mould engineering has become an area of constant innovation and technical refinement.

The creation of a mould involves more than just forming shapes—it requires careful attention to every design detail. Engineers analyze how materials will flow, cool, and solidify to guarantee that each finished piece maintains structural strength and dimensional stability. High-quality mould design minimizes waste, supports efficient mass production, and maintains uniformity between production cycles. This level of precision allows manufacturers to meet strict standards required in industries such as beverages, cosmetics, and pharmaceuticals.

Technological advancements have reshaped the way moulds are designed and produced. Computer-aided design and simulation systems allow engineers to test ideas virtually before any physical work begins. By using these tools, manufacturers can detect and correct potential issues early in the process, saving time and reducing material use. Additionally, automation in machining and assembly ensures smoother production with greater accuracy, enhancing both output and consistency.

Material choice is another critical factor that determines the performance and longevity of moulds. Using durable metals and applying proper treatments help resist wear, corrosion, and deformation under repeated use. Modern surface finishing techniques not only improve durability but also ensure clean releases during each production cycle, preventing imperfections and downtime. These factors together contribute to improved efficiency and long-term value.

Sustainability has also become central to manufacturing strategies. Energy-saving production systems, optimized cooling channels, and environmentally responsible material sourcing reflect a broader commitment to reducing waste and carbon emissions. Manufacturers are balancing the need for industrial productivity with global environmental priorities, ensuring their processes align with modern ecological expectations.

Customization is equally important in meeting diverse client needs. With growing market demand for unique designs and branding elements, mould engineers now develop tailored solutions to match specific shapes, dimensions, or functional requirements. This flexibility allows brands to differentiate themselves while maintaining reliable performance and cost efficiency.

Overall, the ongoing progress in mould design reflects the industry's evolution toward precision, sustainability, and adaptability. Each improvement in design, material, or process supports higher efficiency and product quality. This commitment to innovation ensures that modern moulding technology continues to advance alongside the global manufacturing landscape.

For more information, please visit https://www.qhpreformmould.com/product/bottle-cap-handle-moulds/.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness